In this article I’ll share two wooden toy woodworking

projects that sell and these are low cost projects which are simple to build.

Snazz it up with a cost of creative paint and you will get high margin on these

toys. Have you seen the prices on premium wood toys for kids these days? They

are exorbitant and it is a huge market. Why not join in with these 2 woodworking

projects as a start.

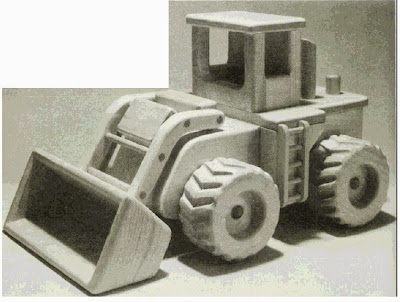

Extractor / Earth Mover Woodworking Plan

This earth mover wooden toy features a moveable shovel that

stops in different positions. This woodworking project should successfully accommodate

most of your child’s heavy earth moving needs for quite sometimes. It is

pictured here built in clear pine but it can be built in a wide variety of

woods, soft maple would be an excellent alternate choice.

Begin construction of earth mover woodworking project with

the body. Rip an 18” length of ¾” stock 4-1/2” wide then set the saw for a 30

degree bevel. Make a crosscut to produce the mitered ends. Cut from the

remainder then make a series of 1/8” deep kerf cuts spaced 1/8” apart to detail

the radiator grille. Cut the side pieces to size then bore the axle holes

before assembly. Use a belt sander or hand plane (or both to form the front end

curves. Cut the cab and remaining body parts to size then use the router with a

5/32” corner rounding bit to ease all sharp corners before completing the body

assembly.

Construct the bucket and bucket arm assembly. Mark the

location of the arm ends and uses a chisel to cut the ¼” deep mortises to

receive them. If you have a brad point or Forstner bit that bores a flat

bottomed hole, use it first then square the corners with the chisel. The bucket

pivot is nailed and glued to the body after the entire bucket assembly has been

completed.

The fat wheels of this extractor woodworking project are

made up by joining two discs of 1-1/8” stock after angled holes are bored to

form the knobby treads. The simple jig used to bore the holes features a

hardwood guide block which has two holes drilled at 20 degrees angles in

opposite directions. Note that these holes must align with the pivot hole so

they are bored from the bottom of the block before the jig is assembled. The

jig may be used with a portable drill or on a drill press. If using a drill

press tilt the table or prop the jig so the bit enters the angled guide holes

squarely. Bore the holes in discs #1 and #2 as indicated. To save layout time

make photocopies of the wheel diagram and attach to each disc with rubber

cement.

Use a 2” dia. Forstner bit to bore the recess in the outer

disc, Part 1, then counter bore for the plug and axle. Saw the discs to final

size after the angled holes are bored to reveal the treads. Use the router to

round over the corners. Sand then glues the wheels to the axles in place on the

body. Finish with several thin coats of shellac or two coats of polyurethane

finish.

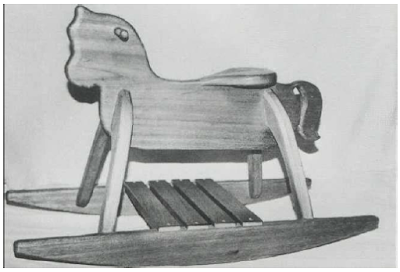

Wooden Rocking Horse Woodworking Plan

Next woodworking project that sell well is Wooden Rocking

Horse. A rocking horse is one of those toys that never goes out of style. The

one shown here is designed for sturdiness as well as stability. The runners are

spread far enough apart to prevent a small child from tipping over, and the

tail is left mostly connected with the body so it cannot easily be broken off.

The wooden horse shown in the woodworking plan was made from 5/4 Philippine mahogany

stepping material, except for the handle, which was formed from a hardwood

dowel. Substitute other woods if you like, but always use quality material for

a toy that can be passed along in your family for generations to come.

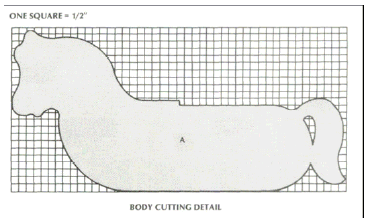

1. Use the pattern provided to make a template for cutting

out the horse’s body (A). Tape or glue the pattern to a 23” length of 5/4 x 12

stock, then cut out the profile with a band saw or saber saw.

2. while the pattern is still attached to the body, bore a

starter hole for the teardrop opening in the tail area, then use a saber saw to

complete the cut. Also, mark and drill a ½” diameter hole through the head for

inserting the handle (F) and two pairs of holes of the same size in the areas

where you want to attach the legs (C )

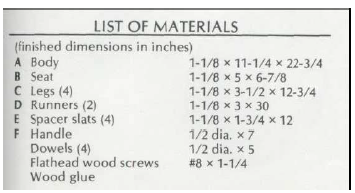

3. Since exact duplicates are needed for the four legs, it is

a good idea to make the leg template out of cardboard. With careful arrangement

you should be able to lay out all four legs on an 18” length of 5/4 x 12 stock.

Cut out the legs with a band saw or saber saw

NOTE: The edge of the notch at the bottom of each leg must

be angled 12” off square so that all four legs will slope in toward the horse’s

middle. If you prefer, cut out the legs without notches first, then figure out

the notches during assembly. The length of the notches is not critical, so long

as they are the same on all four legs and the tips of the legs remain above the

bottom of the runners after assembly.

4. Lay out the two runners (D) on one side of a 31” length of

5/4 x 12 stock. Set them closely together so that enough width remains on the

board for cutting out the seat.

Those are woodworking projects that sell well. Now give it a

try and earn money from it!

Check out other woodworking projects that sell:

- Baby Cradles Woodworking Plan

- Heart Shaped Cheese Box

- Painted Pine Frames Woodworking Plan

Check out other woodworking projects that sell:

- Baby Cradles Woodworking Plan

- Heart Shaped Cheese Box

- Painted Pine Frames Woodworking Plan

No comments:

Post a Comment