Picture Frames Woodworking Plan

Everyone needs more picture frames ! That's why I share picture frames woodworking plan in Woodworking Projects that Sell blog post series. By far this is one of our highest volume in sales. The best thing about it is that it is super make with versatility for different designs

Painted Pine Frames Woodworking Plan

Our first two frames are made from pine and are great candidates for a paint finish. They feature standard moldings available at wellstocked home centers. for all the frames its best to cut the rough materials about 2 or 3 in longer than necessary before ripping to width or machining.

Frame 1 uses base cap molding (No. WM 166) and flat pine stock. Rip four 3/4 x 1-1/4" pine pieces and glue lengths of 1/4 x 1-5/8" lath to each. Place them face to face with the edge of one piece flush with the adjoining piece. Using spring clamps to hold the assembly while the glue sets. Then, spread glue on the back of the molding and clamp it to the top of the lath (Photo 1). Make sure that the outer edge of the molding aligns with the flush edge of the flat stock assembly of the woodworking project.

Next step of the woodworking project is cut the four laminated frame members to size with a miter saw (Photo 2). Use a small brush to spread glue on the mitered ends and assemble the frame in a miter clamp (Photo 3). Check that all corner joints remain tight as you tighten the clamp. After the glue has cured, remove the frame from the clamp and drive small brads into the corners to reinforce the joints of picture frame woodworking project. Next rip pieces of 1 x 2 to 1/2" thick and miter them to fit around the perimeter of the frame woodworking project. Apply glue and clamp them to the frame with spring clamps (Photo 4).

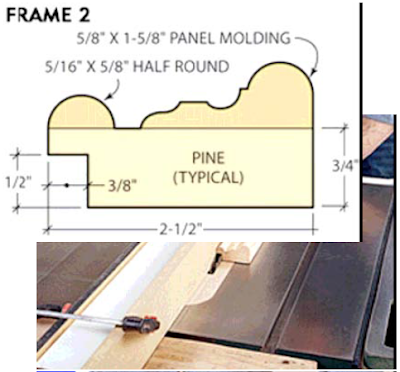

Frame 2 features a woodworking panel molding (No. WM 8174) and a 5/8" half round (No. WM 123), glued to 1 x 3 pine. After cutting the stock to rough length, spread glue on the back of the molding and use spring clamps to hold it to the 1 x 3 until the glue sets. Keep the panel molding flush to one edge and the half round flush to the opposite edge. When the glue is dry, use a dado blade in your table saw to cut the rabbet along the inner edge of the 1 x 3 (Photo 5), Then, miter the frame stock to exact length.

Since this frame is wider than the firs, you can use No. 0 woodworking joining plates to reinforce the corners and eliminate the need for brads. Mark center lines for the plate slots in the mitered ends of the frame stock and cut the slots (Photo 6). Spread glue on the mitered faces, in the plate slots and on the plates, and assemble the woodworking pieces in the frame clamp to pull the corners tight. After about 20 minutes, use a small chisel or putty knife to remove any glue that has squeezed from the joints.

To finish these painted frames woodworking, first lightly sand with 150- and 220 grit sand paper. Then apply a woodworking aerosol spray finish, following the manufacturer's instructions. We used Rust Oleum Hammered Gold (No 7210) and Hammered Silver (No 7213) for our frames.

Hardwood Frames Woodworking Project

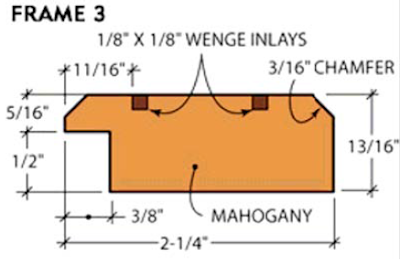

Another approach to building frames is to use hardwood with either a clear or stained finish. In each of the following woodworking designs, we've combined different woods to create woodworking patterns of contrasting colors and textures. After building four oversize pieces of frame stock for each design, use a dado blade or router table to cut the 3/8" wide frame rabbet on the inner edge of each woodworking piece. Then use a miter saw to cut the pieces to precise length and join the corners with plate joints. Frame 3 is constructed of mahogany with wenge inlay. Begin by ripping 13/16" mahogany to 2-1/4" wide. Crosscut the stock to rough length, then readjust the saw blade and cut two 1/8" deep kers in the face of each piece. use a band saw to rip 1/8 x 1/4 inch inlay strips of wenge. Run a bead of glue into each saw kerf and press the inlay strips into place. Use spring clamps to hold them while the glue cures (Photo 7). When the glue is dry, use a plane or sharp cabinet scraper to trim the wenge flush to the mahogany surface. Then, install a chamfer bit in your router table and bevel the two top edges of the woodworking frame stock.

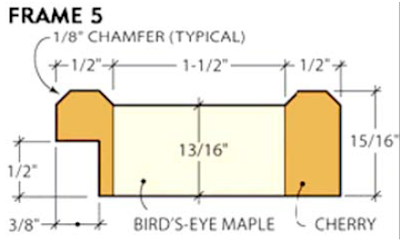

Woodworking frame 4 and 5 are variations on the same theme. For the first design, rip curly maple strips to 1/2 x 1-1/16 inch and glue them to the edges of a 13/16 x 1-1/2 inch walnut field (Photo 8). Keep all pieces flush on the back side of the frame.

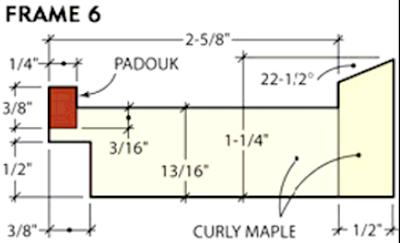

For the second variation, rip 1/2 inch thick cherry stock to 2-1/2 icnh wide. Use a router table with a chamfer bit to shape all four edges of the cherry, then rip the molded stock into 15/16 inch strips (Photo 9). Glue these strips to both edges of a birds eye maple field. For Frame 6, we've chosen curly maple for the field and raised outer band, with a padauk inlay that accents the woodworking inner edge. After ripping the maple stock to width, use a dado blade or router table to cut a 3/16 inch deep x 1/4 inch wide rabbet along one edge of each of the four frame pieces. Then cut pieces of padauk to fit the rabbet in each piece. Glue the inlays in place, securing them with strips of masking tape until the glue sets (Photo 10).

To make the outer band, rip a 22-1/2 inch angle on the edge of a 1/2 inch thick piece of maple. Re adjust your saw to 90 degree and rip this beveled strip from the board. With four band strips made, glue each to the outer edge of the maple field woodworking pieces (Photo 11). After sanding to 220 grit, we finished our hardwood frames with clear shellac. This finish is easy to apply, it dries quickly, and it won't react with delicate artwork and mounting materials. Brush on a light coat with a good quality bristle brush and let dry for at least 2 hours. Lightly sand with 320 grit paper to remove any roughness, and dust off. Apply one or two additional coats as needed. Then the last coat is dry, rub it with 4/0 steel wool for a warm, satin gloss.

Woodworking Mounting Equipment

Now that you have your wooden frames ready, its time to gather the materials for mounting. you can buy what you need at any well stocked art supply store. Photos and prints are typically mounted within a broad mat board window that highlights the artwork. Mat board is available in a variety of colors and a few textures as well. Make sure to get acid free, or archival, mat board to protect the artwork from deterioration. This same material can be used ass the mounting board behind the artwork. You'll also need archival mounting tape. This tape is made of linen cloth and is activated by wetting its glued surface. Backing board, installed behind the mounting board to keep it flat, can be either stiff corrugated cardboard or foam core stock. After the backing board, you'll need kraft paper to act as a dust cover over the back of the frame, a glue stick is a convenient way to attach the paper to the frame.

Most artwork requires a pane of glass to protect it from dirt and changes in humidity. In most cases, normal window glass will work, although a special ultraviolet protective glass is available to help prevent fading. Non glare glass is also used for framing. However, this type has a slightly dull appearance. Acrylic sheet can be a practical alternative to glass especially if weight is an issue. But acrylic scratches easily, attracts dust and doesn't have the same degree of transparency as glass. As for special tools, you'll need a straight edge and a mat cutter. Mat cutters come in a variety of configurations, ranging from basic $15 models to professional versions costing a few hundred dollars. We achieved good results with a medium priced Logan Model 3000 Pro-Am mat cutter and adapt a rule straight edge and ruler.

Mounting The Artwork

Measure and mark the size of your mat and mounting boards. It's best to work from the back of the boards to prevent soiling the face. Place the boards on a piece of scrap card board and use a utility kniefe and straight edge to cut both pieces to size. Position the artwork on the mounting board and mark the corners with light pencil marks. Rip two 1-1/2 inch long pieces of linen mounting tape and moisten about 1/2 inch of each piece. Adhere the tape to the back side of the artwork, along the top edge so that about 1 inch extends beyond the top. When the glue dries, turn the piece face side up and position it on the mounting board. Rip two more strips of tape, each about 3 inch long and moisten them. Apply them accross the extending tape strips so the artwork is hinged to the mounting board (Photo 12). This system allows the print to expand and contract with changes in humidity, without wrinkling.

Mark the cutlines for the opening, or window, on the back side of the mat board. Typically, a mat extends over the image by no more than 1/4 inch on each edge. use the straight edge and mat cutter to make the cuts (Photo 13). It's a good idea to practice on scrap board to learn how to start and stop the cuts exactly at the corners. Place the cut mat over the mounted print (Photo 14). It's not necessary to attach the mat since the whole assembly will be sandwiched in the frame.

Turn the frame upside down and install the glass. Then place the matted print into the frame (Photo 15). Cut the backing board to size and place it over the mounting board. Use framer's points to hold the back in place (Photo 16). You can use a special driving tool or a flat blade screwdriver to install the points. On hardwood frames, the driving tool is worthwhile since the points are a bit harder to install.

Cut a piece of kraft paper slightly larger than the overall frame size. Rub a glue stick on the back side of the woodworking frame and apply the paper, letting it overhang on all edges. Press the paper to the frame to get a good bond and use a straight edge and utility knife to trim it 1/8 inch in from each edge. The simplest method of hanging a frame is to use a sawtooth type hanger. Center the hanger on the back of the top rail of the frame and drive brads to hold it in place (Photo 17). On a hardwood frame, use an awl or bore small pilot holes for the brads. Large or heavy frames are best hung with picture wire. Bore pilot holes, and install screw eyes or D-ring hangers in the side frame rails about 3 or 4 inch from the top edge of the frame. String a length of picture wire between the hangers, leaving about 1-1/2 inch of slack. Twist the wire together to lock it to the hangers (Photo 18)

Read other woodworking projects that sell below:

Thank you, very informative

ReplyDelete