Sometimes, when I am sitting alone in my workshop, I take up one or more pieces of choice wood and feast my eyes on the various colors that make up the character of the grain.

To hold the wood up to the light and see the way the grain shimmers and glows, to see how two pieces of wood look when they are held side by side - and then to imagine how the wood might be used for a special project - these are unique quality time experiences that should not be missed

The project draws its inspiration from one of my alone in the workshop musings. The problem was how to bring together three relatively small pieces of choice exotic wood - a scrap of ebony salvaged from an old long gone piece of furniture, a silver of silver sycamore veneer left over from a marquetry project, and a short length of dark wood that I've been using to prop open the door.

Anyway, I tossed all sorts of ideas around in my head - a small piece of laminated jewelry? a turning? a handle for a knife? a drawer pull? And then it came to me.. why not make a small clock case!

Making The Woodworking Clock Case

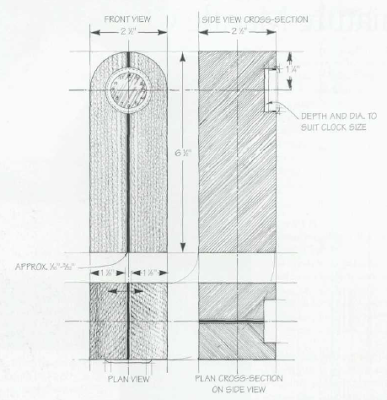

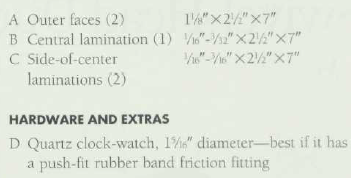

First thing, before you do anything else, you need to search out a miniature watch clock and a Forstner drill bit sized to fit. For example, as my clock (described as a watch clock miniature suitable for block and drilled recess mounting) measures slightly under 1 5/16" diameter across the span of the back and about 1/4" in depth, I reckoned that I needed a drill size of 1 3/8".

when you have obtained the clock watch and the drill size to suit, take your chosen pieces of wood and plane and sand the mating faces down to a true finish. This done, smear white PVA glue on the mating faces and clamp up.

Having waited for the glue to cure, set the compass to a radius of 1 1/4", spike it on the center veneer at a point about 1 3/8" down from top center, and then strike off a 2 1/2" diameter half circle. When you are happy with the way the lines of the design are set out on the wood, mvoe to the band saw and cut out the curve that makes the top of the case. Use a square to mark out the baseline, double check that it is absolutely true, and then cut off the waste with a small toothed back saw. It's important that the baseline is square tot he center line of the block, so spend time getting it right. When you are sure that the block sits square and true, move to the drill press and bore out the recess for the clock. Bore down to a depth of about 3/8".

Having bored out the recess, take a scrap of sandpaper and rub down the inside of the recess, so that the clock watch is a tight push fit. If necessary, use a straight gouge to cut a little scoop for the hand setting knob that sticks out at the side of clock case. When you have achieved a good fit of the clock watch in the recess, rub the whole block down on a sheet of fine grade abrasive paper. Finally, burnish the block with beeswax, slide the click watch mechanism in place and the project is finished.

Special Tip: Lapping

The best way of rubbing the faces of the block down to a smooth, true finish is to use a technique known as lapping. All you do is mount a sheet of medium grade abrasive paper to a slab of 1/2" thick plywood so that the grit side is uppermost. Then clamp the slab in place on the bench. In use, the workpiece is rubbed in the direction of the grain, backwards and forwards. The procedure is rerun with finer and finer grades of paper

Step by Step Woodworking Stages

1. Pass radius to 1 1/4" and strike off the arc that makes the top of the case. Make sure that you spike the compass point on the middle of the fine black laminate

2. Leaving cut the curve on the band saw, run the faces of the block down on a series of lapping boards. Work through the grit sizes, from a medium fine through a super line flour grade. Only work in the direction of the grain, and be careful that you don't blur the sharp corners.

3. Having selected a Forstner bit sized to fit the diameter of your clock, sink a recess to the appropriate depth. The success of the project hinges on the hole being perfectly placed, so spend time getting it right

No comments:

Post a Comment